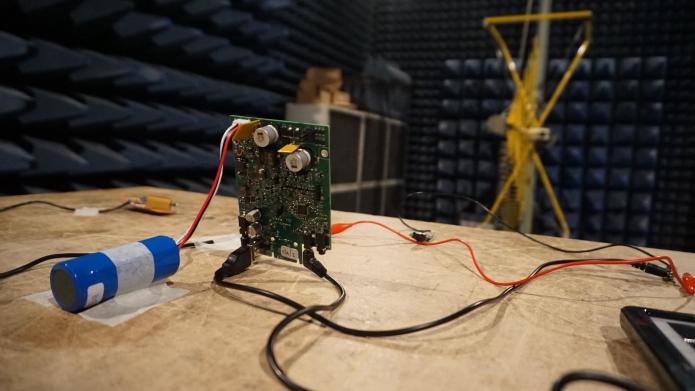

We want to tell you more about an important milestone that we have reached. Last week we put our nowlight samples through Electromagnetic Compatibility (EMC) and Electrostatic Discharge (ESD) testing. Electronic devices are required to pass these tests in order to demonstrate that they are safe and reliable.

These tests may sound like rather dry subject matter but as we will try to demonstrate they are actually rather interesting. What’s more, all the tests are conducted in a room that looks like its part of the set from a sci-fi film!

The emissions from the nowlight PCB (the circuit board) are measured at different light outputs and in different charging states

There are two main purposes of EMC testing. The first is to make sure that an electronic device does not unintentionally emit electromagnetic energy in a way that could disrupt other devices. The second is to make sure that an electronic device does not malfunction or break down in the presence of electromagnetic emissions from other sources.

Electronic devices must be carefully placed when running EMC tests. For example, if the nowlight and SatLight overlap it can be difficult to identify which is the source of electromagnetic interference.

After the tests have been completed the results are reviewed to see if an electronic device is creating emissions above legally allowed limits or if it is vulnerable to emissions from other sources. The good news is that nowlight and SatLight comfortably passed all of the tests!

Electrostatic Discharge (ESD) is the sudden transfer of electricity between two electrically charged objects. In severe cases static discharge can cause bodily injury, and mechanical or electrical failure. In short, there is a risk that static discharge could break a nowlight.

As part of ESD testing, a technician uses an ESD gun to ‘zap’ nowlight with static electricity on all the metal surfaces on the outside of the product, such as the screw heads and the USB port. If exposure to static electricity causes the PCB inside nowlight to fail, it may need to be redesigned. However, we are pleased to report that the PCB passed all the tests.